SITUATION

The presence of non-value-added material in ore, gangue, is ubiquitous in the Mining industry today. Its presence, and effective removal, is primarily the requirement for any ore processing conducted industrially and the main driver of cost.

CHALLENGE

All separation processes must take into account the presence, composition, and amount of these minerals in order to effectively isolate the metal of interest. From flotation, to heap leaching to dense media separation, there is centuries of knowledge built solely on handling gangue, which when separated is stored in tailings facilities creating only cost and no value.

SOLUTION

Utilizing our understanding of microbiological processes, Allonnia is developing a technology which selectively dissolves gangue minerals from ores and concentrates. Microbial interactions with mineral surfaces are a fundamental aspect of life on earth, where organisms utilize the composition of those minerals for critical chemical processes inside them in order to grow and multiply. While those chemical reactions happen quickly, the dissolution of particular atoms from a mineral surface happens very slowly in nature. Allonnia’s scientists have learned the chemical transformations these microbes create and have found a way to leverage that understanding to develop a process which can run on mineral processing timelines.

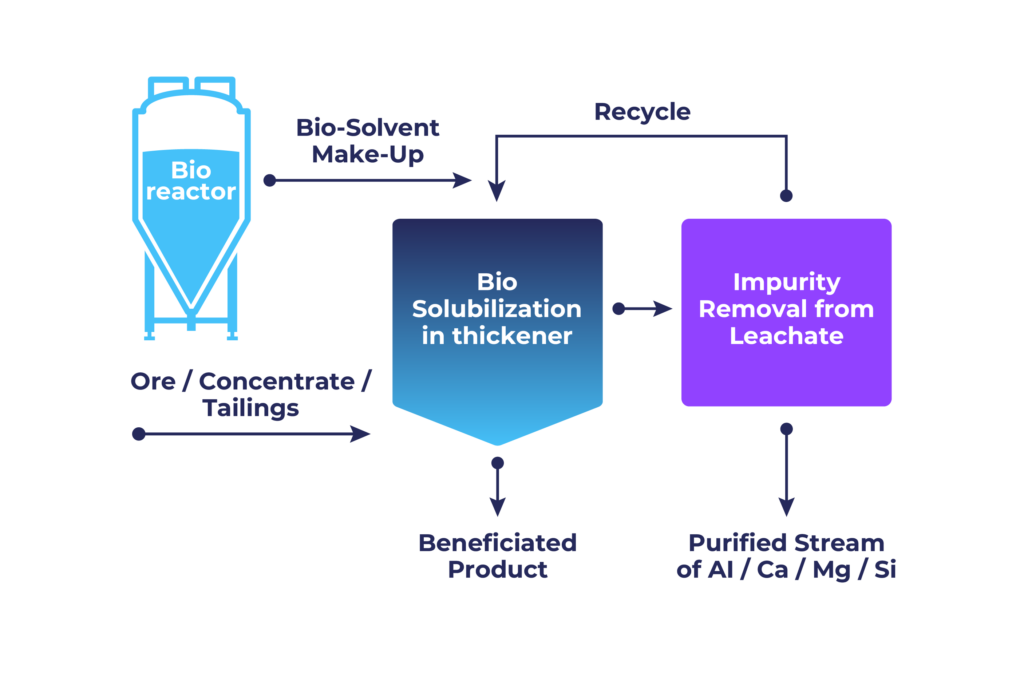

At its heart, Allonnia’s Selective Solubilization utilizes the metabolites of specific organisms grown under particular conditions in a bio reactor to generate a “Bio-Solvent”, which can dissolve the gangue in a known continuous chemical process. Once removed, the beneficiated ore or tailings is further processed as needed on site, while the impurities in Bio-Solvent are removed. Those gangue impurities (soluble Al, Si, Ca and or Mg) can be recovered and potentially utilized in other industries, depending on purity. Additionally, in the cases of Mg and Ca, a separate step to mineralize these metals can be conducted to sequester CO2. Lastly, the bio-solvent can be recycled and returned to the bio-reactor to close the loop of the process.

A simple flowsheet of Allonnia’s process for selectively removing gangue from ore.

RESULTS

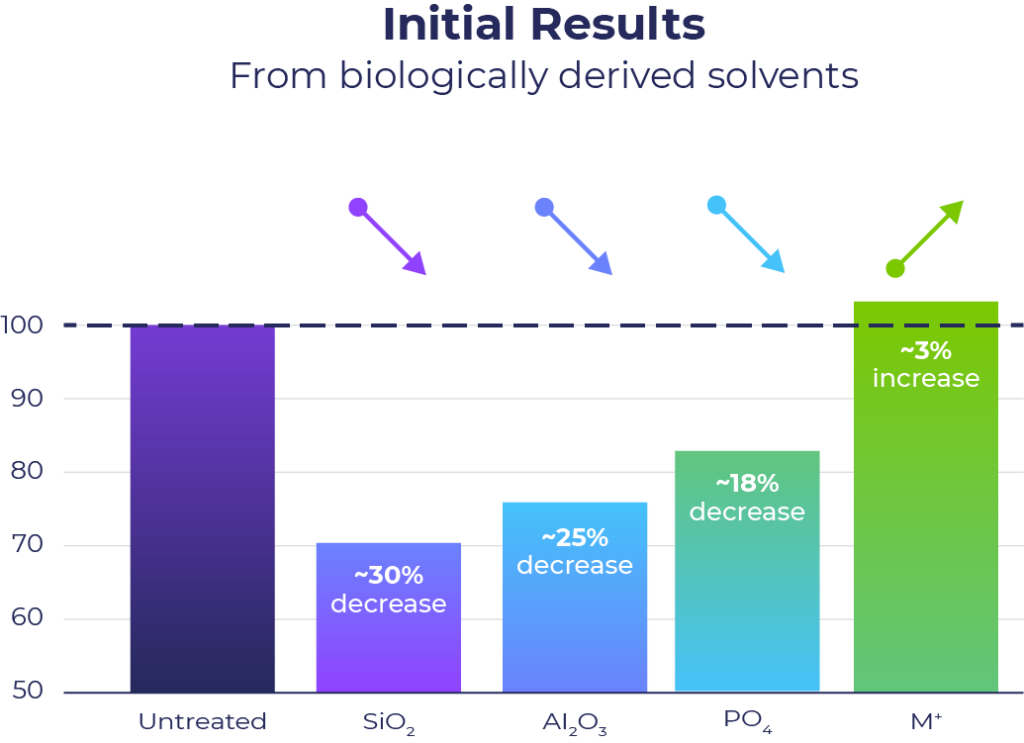

Our initial results are illustrated below. In a simple benchtop experiment, we were able to dissolve aluminum and silica-based minerals from an ore sample under standard mixing conditions. Additionally, we were able to measure an increase in the grade of the metal of interest, confirming the selective removal of the gangue minerals.

Allonnia’s initial results showing the removal of aluminum and silica from an ore and the corresponding increase in grade of the metal of interest.

BENEFITS

Reducing gangue content in ore or a process concentrate can provide substantial processing benefits. Gangue reduction in ore allows for an improved throughout, increasing production. Alternatively, production can be maintained with lower volumetric flows, reducing energy and handling costs. The higher head grades in these ores could also improve separation in flotation or recovery in heap leaching. When applied to flotation concentrates, Allonnia’s Selective Gangue removal can reduce impurities, such as silica, calcium and magnesium to improve the downstream smelting efficiency, filling available capacity, while reducing slag. The removed calcium and magnesium can also be utilized to sequester CO2, providing a unique capability to support the overall sustainability goals of the organization.”

Click here to learn about our partnerships.