Leveraging the power of nature in the form of rising air bubbles to rapidly separate and concentrate harmful PFAS contaminants ready for destruction

SAFF is a proven and award-winning solution to permanently remove PFAS from contaminated water for net positive impact to the environment.

From landfill sites, airports, and military bases to water treatment plants and industry complexes, SAFF is a leading technology choice for PFAS remediation.

SAFF is manufactured by EPOC Enviro and distributed in North America by Allonnia.

SAFF has successfully treated hundreds of millions of gallons of PFAS contaminated water. It has been deployed in many applications including landfill leachates, groundwater and process water.

SAFF provides the lowest operating cost of any PFAS treatment system available today. The plug and play design can be operating within a few hours once onsite. It simply requires a power lead and connection hoses to commence.

SAFF contributes zero harm to the environment by using no consumables, minimal energy and labor, and produces no waste other than PFAS concentrate. Paired with an appropriate destruction technology, create a closed loop operation with SAFF to treat all PFAS onsite.

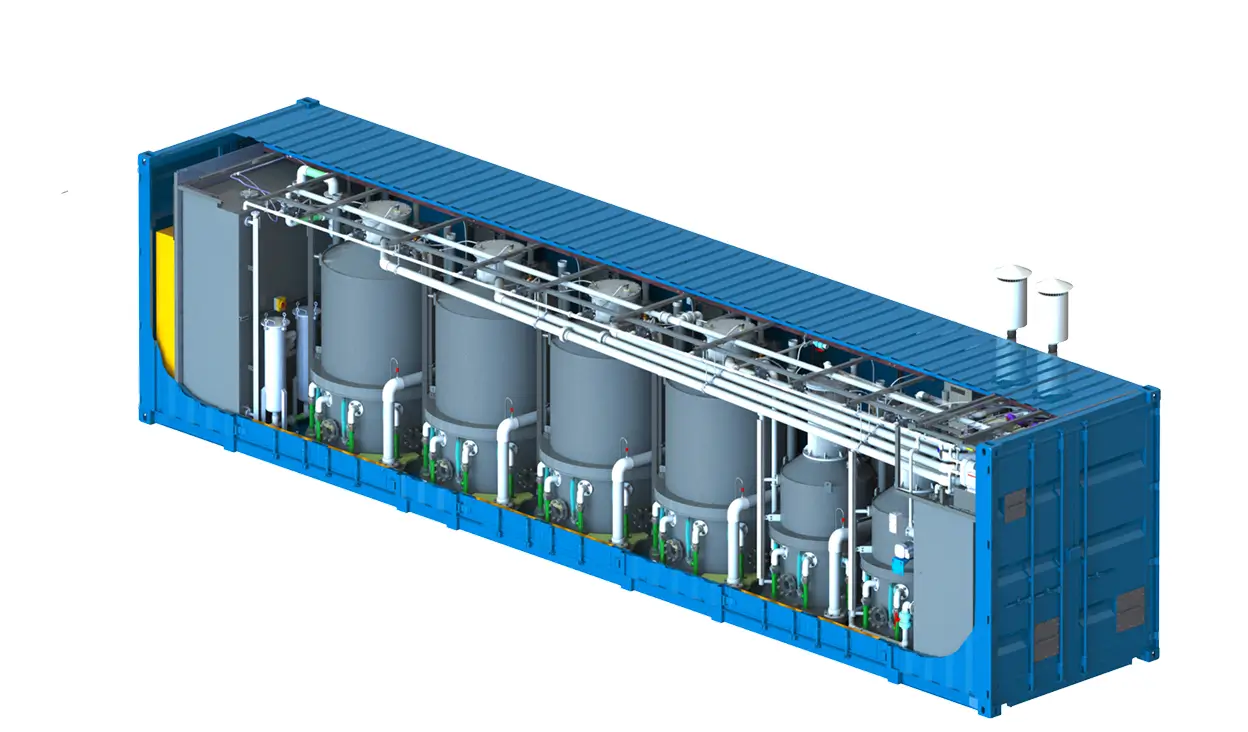

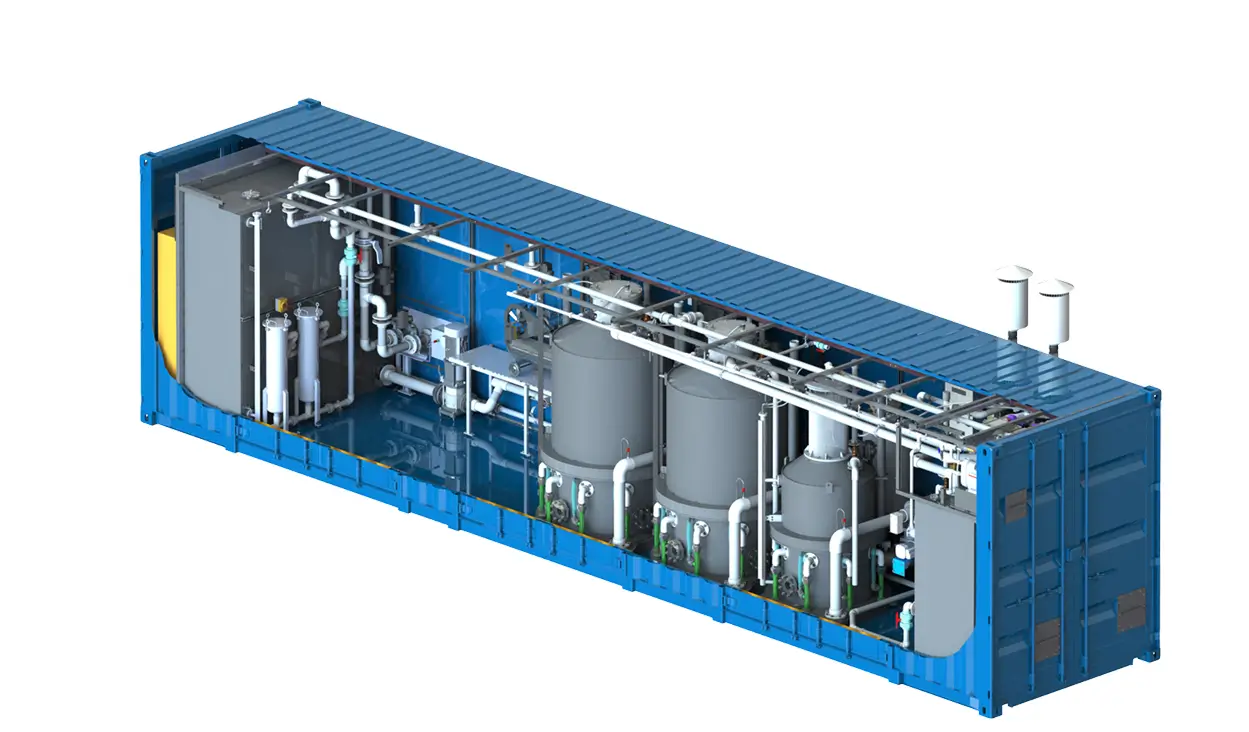

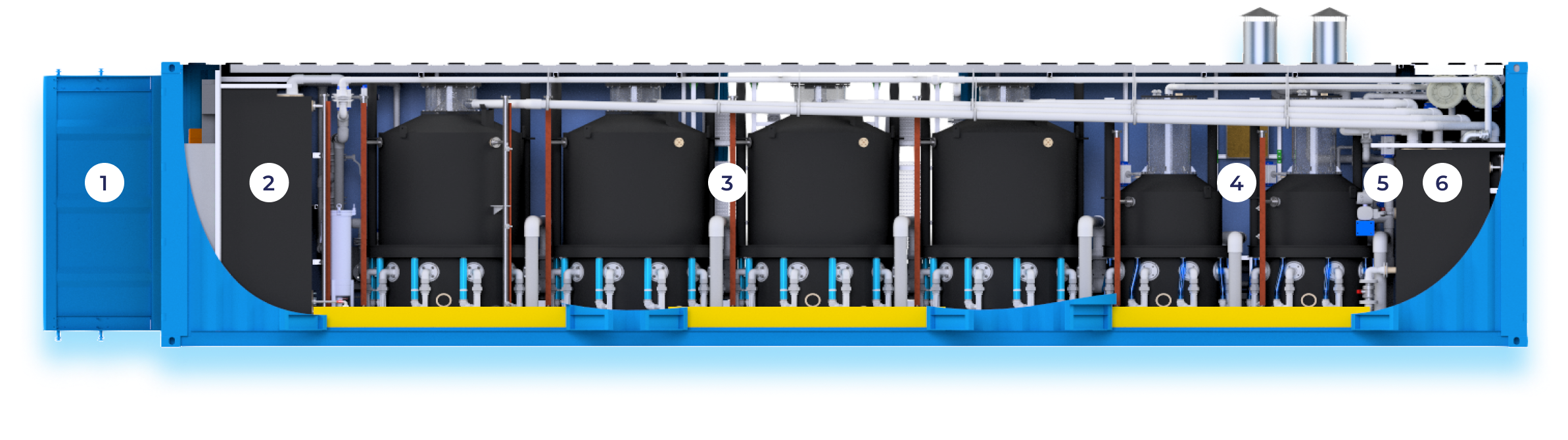

The SAFF family includes containerized, weatherized units (SAFF40, SAFF20) for year-round operation without permanent structures, and a mobile SAFF10 for flexible deployments. All units are supported by 24/7 real-time worldwide monitoring for continuous oversight and responsive intervention under agreement.

SAFF can manage the presence of co-contaminants, even at high concentrations. It quickly achieves a highly enriched, low volume PFAS concentrate, without the use of adsorption media, enabling effective pairing with portable destruction technologies for onsite closed loop remediation.

SAFF technology has successfully treated tens of millions of gallons of PFAS contaminated water. It has been deployed in many applications including landfill leachates, groundwater and process water.

SAFF technology provides the lowest operating cost of any PFAS treatment system available today. The plug and play design can be operating within a few hours once onsite. It simply requires a power lead and connection hoses to commence.

SAFF contributes zero harm to the environment by using no consumables, minimal energy and labor, and produces no waste other than PFAS hyper-concentrate. Paired with an appropriate destruction technology, create a closed loop operation with SAFF to treat all PFAS onsite.

SAFF’s containerized, weatherized design enables year-round operation with an installation that avoids permanent structures. 24/7 real-time worldwide monitoring ensures continual oversight and intervention as needed under the agreement.

SAFF can manage the presence of co-contaminants, even at high concentrations. It quickly achieves a highly enriched, low volume PFAS concentrate, without the use of adsorption media, enabling effective pairing with portable destruction technologies for onsite closed loop remediation.

The original, high-performance PFAS treatment workhorse

Full-scale performance for lower-flow applications

Big impact in a small footprint

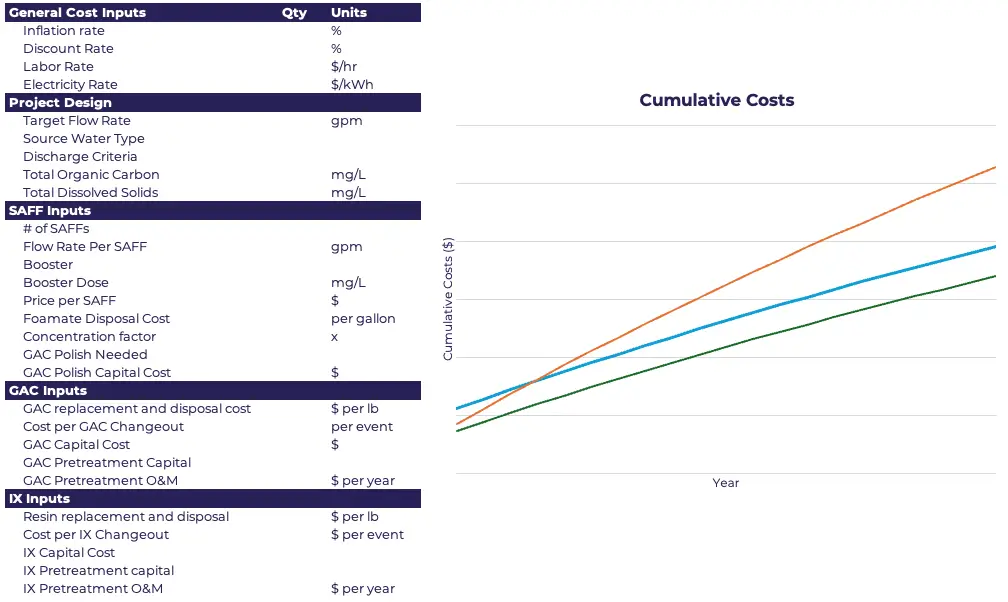

Whether you’re exploring PFAS treatment for the first time or looking to improve your current system, we’ll show how SAFF compares on cost and performance for your site.

gallons treated

Automated control of the system to include optimization with the Allonnia booster. Allows for 24/7 remote telemetry requiring minimal on-site operator supervision.

Since 2018, across three continents, SAFF technology has proven to remove a full spectrum of PFAS, long and short chain molecules, from complex in-feed chemistries to yield a destruction-ready hyper-concentrate.

SAFF technology can strip PFAS from groundwater at contaminated sites and efficiently remediate over a range of flow rates.

SAFF is capable of treating to the standards needed for drinking water applications.

SAFF can also treat complex landfill leachate waters as it’s not limited by high DOC, TOC, TSS, TDS or the presence of other organic and inorganic compounds. As a result, it requires minimal to no pre-treatment to effectively remove PFAS.

SAFF can treat discharge from industrial manufacturing processes, reaching publicly operated treatment works (POTW) permit limits. The unit can easily pair with an existing water treatment system.

2023 Innovation by

Design Award

Fast Company

Allonnia’s Foam Fractionation Booster is a suite of products proven to enhance SAFF’s capabilities in removing short chain PFAS with only a low dosage. It pairs seamlessly with SAFF and is ready to use upon deployment – no additional hardware is required.

The installation will treat groundwater at an ex-AFFF site using SAFF and Aquagga’s HALT destruction technology.

A pilot will use SAFF with electrochemical oxidation destruction technology to treat groundwater and surface water at a government site.

After a SAFF bench scale test in lab, SAFF was selected for a full scale implemention to treat the site’s groundwater.

Producing >1 million gallons of clean water, the 3 month pilot removed targeted long and short chains with SAFF plus a booster, and successfully destroyed the PFAS using electrochemical oxidation.

A planned 8-week pilot completed in 5 weeks due to highly successful SAFF performance.

A pilot using SAFF and plasma vortex destruction technology treated groundwater at a New England government site.

SAFF operates as the ‘hub’ in Grand Rapids, MI, with transport of the concentrate to a destruction vendor for disposal.

Producing clean drinking water for >174,000 residents, the closed loop system operates SAFF and electrochemical oxidation for destruction.

A 6 month trial will start at a government location using SAFF to treat groundwater and testing multiple destruction technologies.

The pilot treated 360K gals of leachate and resulted in 600x concentration factor.

Supporting the Australian Department of Defence’s ex-firefighting training area, it’s the longest running SAFF unit producing >37M gals of clean water.

Starting in November 2022, SAFF has produced >740,000 gals of clean water for this S. Wales landfill.

SAFF separated and concentrated PFAS from 38K gals of complex leachate.

Treating >530K gals since it’s start-up in March 2023.

SAFF treated 94K gals of site water runoff during excavation.

SAFF removed PFAS from a highly contaminated foam deluge system starting in October 2022

During a 3 month full-scale trial, SAFF produced 3 million gallons of clean water for a Swedish landfill.

A pilot starting in November 2022, treated millions of gallons of landfill leachate.

Removing PFAS from 900K gallons of complex landfill leachate.

A full-scale SAFF40 deployment treated 3 million gallons of leachate.

During a treatment trial conducted near an airport with several collections pond with contaminated surface water runoff, SAFF successfully removed PFAS with >C6 chemistry.

During a 3 month field trial, SAFF removed PFAS from 8 million gals of leachate.

SAFF40 treated landfill leachate at 97 GPM for three years, achieving:

During a four month deployment, a SAFF20 system treated landfill leachate at 61 GPM, achieving:

A SAFF20 system processed wastewater and surface water at 15 GPM, achieving:

Treating 37 GPM of groundwater and surface water at a DoD site, achieving:

SAFF and a destruction technology treated leachate and groundwater in an eight-month pilot for an EU-funded LIFE project, achieving:

10-month trial of a closed-loop PFAS remediation approach using SAFF and an on-site destruction technology.

SAFF treats another foam deluge facility, successfully treating 250K gallons of PFAS contaminated water.

A SAFF40 system processed surface run-off at 44 GPM from April 2024 to October 2025, achieving:

A SAFF20 system treated AFFF-contaminated water with ash at a rate of 44 GPM, achieving:

Our dedicated Customer Support team is ready to assist you with any questions or concerns you may have.

Please call 1-857-702-2053

Our offices are open Monday to Friday: 9:00 am – 5:00 pm (EST).