Across the globe, environmental professionals face the mounting challenge of PFAS water treatment—with cost often being the biggest barrier to action. For many, physical sorptive media such as granular activated carbon (GAC) and ion exchange resins (IX) have been the go-to options. But as influent concentrations rise and sustainability pressures mount, more and more teams are asking: is there a more efficient way that also reduces environmental impact?

In our latest Allonnia Insights webinar, we took a deep dive into the economics of SAFF® —the Surface Active Foam Fractionation system manufactured by EPOC Enviro.

Spoiler: it’s changing the PFAS treatment game and redrawing the cost curve.

Why the Economics of PFAS Matter More Than Ever

Conventional PFAS treatment technologies, such as GAC and IX, can come with a hefty price tag—often driven by recurring media changeouts, pretreatment requirements, and unpredictable waste management costs. SAFF was designed to shift that paradigm.

Instead of adsorbing PFAS, SAFF selectively separates and concentrates it. The result? Lower disposal volumes ready for destruction and reduced reliance on consumables.

SAFF’s PFAS Removal Cost Drivers

The economics of SAFF differs from legacy methods. Here are the biggest impact areas where SAFF is differentiated:

- Concentration factors, not PFAS loading, drive O&M costs due to the impact of waste disposal

- Minimal pretreatment needs, even for complex influents like landfill leachate

- No reliance on physical media like GAC or IX, slashing recurring spend

- Modular, remotely operated system that is up and running in hours

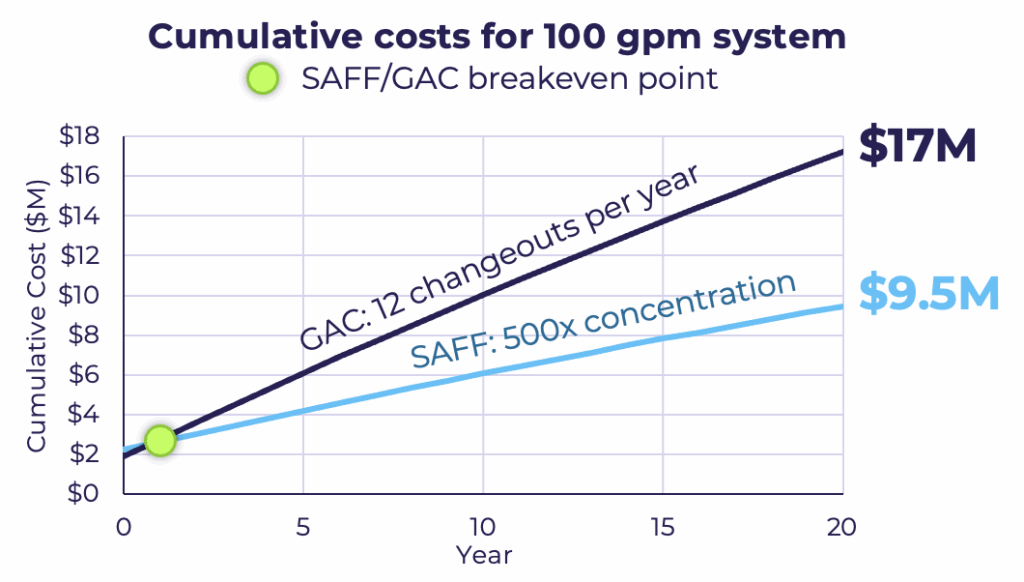

While capital costs may be higher upfront, the long-term ROI speaks for itself—especially for high-throughput or high-concentration sites.

Scenario of SAFF compared to sorptive media. See more details and scenarios in the full webinar.

Results from the Field

From military bases to municipal landfills, SAFF has proved itself in some of the toughest PFAS treatment scenarios. One pilot demonstrated 99.9% PFAS removal and generated so little waste that the disposal tank sat nearly empty. Another project eliminated the need for polishing treatment altogether.

These case studies—and the cost comparisons behind them—are all shared in the full webinar replay.

DriversWant to see the numbers? Watch the replay.

In the session, Rob Rappold, Allonnia VP of Business Development, and Dr. Jason Hnatko, Allonnia Engineering Manager, unpack:

✅ How the SAFF process works

✅ How to think about PFAS treatment cost drivers

✅ Real data comparing SAFF to carbon-based systems

✅ Where SAFF makes the most economic and environmental sense

Watch the Webinar [requires form fill in order to view]