AN INNOVATIVE PROCESS TO

INCREASE MINERAL

PRODUCTION AND GRADE

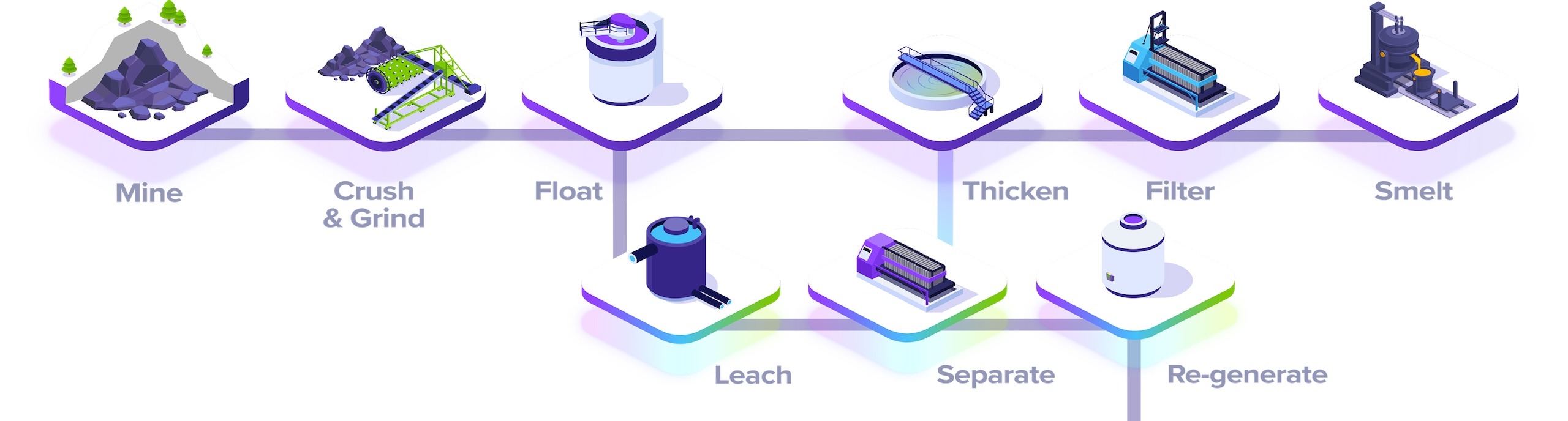

Our D-Solve solution is a bolt-on technology that transforms the traditional mineral processing flowsheet. D-Solve not only increases the value of your concentrate but can create additional value by turning waste into feedstocks for other industrial processes or a potential path for CO2 sequestration.

The heart of the technology are the Allonnia Biosolutions™, a powerful, naturally derived solution generated by microbes that selectively dissolve unwanted gangue while purifying valuable mineral concentrates.

EXPERIENCE INCREASED MINERAL production:

Our selective biosolution can provide a paradigm shift in reducing the need for grade or recovery trade-offs.

D-Solve can unshackle mine planning restrictions designed to mitigate against difficult to process ores by reducing operational expenses.

Using an agitated leach tank and well established water treating technology, we have engineered our solution to be easy to operate and maintain in readily available equipment.

Our D-Solve technology is simple and easy to use and enhances the performance output of existing mechanical equipment to reduce energy requirements and lower the overall cost of production.

EXPERIENCE INCREASED MINERAL production:

Our selective biosolution can provide a paradigm shift in reducing the need for grade or recovery trade-offs.

Our D-Solve process bolts onto an existing production line to elevate the overall grade.

D-Solve can unshackle mine planning restrictions designed to mitigate against difficult to process ores by reducing operational expenses.

Using an agitated leach tank and well established water treating technology, we have engineered our solution to be easy to operate and maintain in readily available equipment.

Use less energy to increase production with potential to sequester CO2 and generate purified streams of gangue which would have reported to tails or slag.

Our D-Solve technology is simple and easy to use and enhances the performance output of existing mechanical equipment to reduce energy requirements and lower the overall cost of production.

Our solution is designed to bolt-on to your existing equipment, optimizing efficiency while maintaining a small footprint.

A stream of flotation concentrate is sent to an agitated leach tank, dissolving gangue minerals.

The purified concentrate is removed by filtration and returned to the main process.

The concentrate impurities are then removed, and the solution is returned to the leaching step.

We aspire to achieve a solution that boosts metal production, reduces energy and unlocks value in mining waste for:

Our dedicated Customer Support team is ready to assist you with any questions or concerns you may have.

Please call 1-857-702-2053

Our offices are open Monday to Friday: 9:00 am – 5:00 pm (EST).